Traitements

thermiques

Quel que soit votre domaine d'activité, HACER s'efforce d'anticiper les évolutions du marché, pour rester au plus près de vos attentes et vos besoins en traitements thermiques sous atmosphère, sous vide et par induction. Pour vos pièces de petites et moyennes dimensions, en petites-moyennes et grandes séries, de différents matériaux métalliques, HACER dispose d'un savoir faire de plus de 50 ans.

Nos traitements

thermiques

Pour plus de détails sur nos traitements, une liste de fiches techniques est à votre disposition sur demande via notre formulaire de contact.

Fiches disponibles : Nitruration - Nitrocarburation - Cémentation - Carbonitruration - Trempe par induction - Traitement thermique des alliages légers - Argenture - Nickel Chimique - Anodisation - Brunissage.

Des technologies

de pointe

Vos préoccupations animent notre quotidien.

HACER est à votre écoute pour travailler avec vous les projets que vous souhaitez nous confier. Un rythme d'investissements soutenu dans nos équipements et une veille technologique constante nous permettent de suivre les évolutions techniques afin de répondre aux exigences du marché et à ce que vous recherchez sur vos pièces.

- augmenter la tenue à la fatigue

- la résistance à l'usure

- coefficient de frottement

- la résistance au choc

- optimiser vos coûts

- augmenter la fiabilité et la qualité de vos produits

- développer votre capacitaire

Trouvez ici toutes les combinaisons possibles chez HACER Traitements Thermiques

Nos

équipements

En fonction du cahier des charges et de la nuance matière du produit, HACER vous propose des procédés adaptés aux pièces confiées.

Four batch

Four à tapis

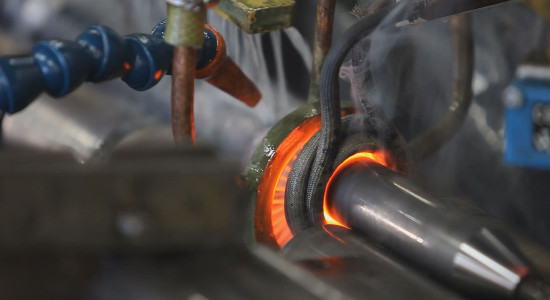

Trempe par induction (HF - MF)

Les

substrats

Afin de répondre au maximum d'applications, nos traitements techniques s'effectuent sur des métaux très divers :

- aciers alliés, non-alliés

- aciers de construction métallique, de nitruration, de cémentation, de carbonitruration

- des compétences humaines et matérielles

- aciers à roulements

- aciers à outils

- aciers inoxydables

- alliages aluminium

- cuivres, cupro-béryllium

Acier

Inox

Cuivreux

Aluminium

Quelques

applications

Ferroviaire

HACER, dont un des process thermiques a été validé par un équipementier, est fier de réaliser le traitement des rouleaux coniques, composants des roulements pour le TGV du futur.

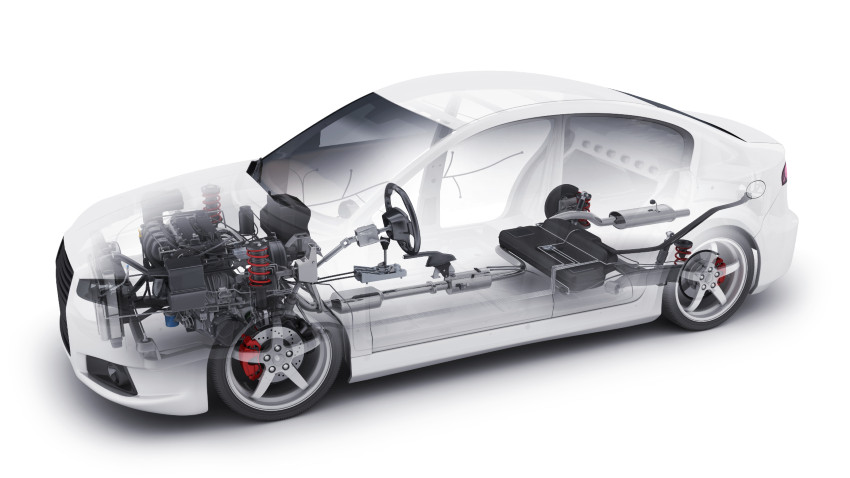

Automobile

Pour un de nos clients roulementier, nous avons mis au point au travers d'un co-développement, un traitement thermique permettant d'accroître de manière significative la longévité de roulements de boîte de vitesse.

Sport de montagne

Spécialisée dans le traitement thermique des aluminiums, HACER leur confère des propriétés mécaniques de service pour augmenter leur durabilité sur vos pièces de fixations de skis (randonnée ou pas), leviers de talon, etc.

Pour les mousquetons d'alpinisme, les pièces que HACER traite en prestation globale subissent un traitement thermique de durcissement dans la masse (7075 T73), ainsi qu'une anodisation sulfurique colorée (OAS).

Vélo électrique

Dans un marché du vélo standard ou VAE (Vélo à Assistance Électrique) en pleine croissance, il a fallu solutionner des problèmes de casse sur un axe de pédale frappé à froid.

Sur des axes de pédale (parfois instrumentés), HACER assure le traitement thermique par une trempe et un revenu spécifique, et leur confère une meilleure fiabilité et robustesse dans le temps.