Traitements

de surface

Quel que soit votre domaine d'activité, HACER s'efforce d'anticiper les évolutions du marché, pour rester au plus près de vos attentes et vos besoins. Spécialisé dans les traitements de surface, tels que dépôts chimiques, électrolytiques, pour pièces de petites et moyennes dimensions, en petites, moyennes et grandes séries, sur différents métaux, HACER dispose d'un savoir faire de plus de 60 ans.

Nos traitements

de surface

Pour plus de détails sur nos traitements, une liste de fiches techniques est à votre disposition sur demande via notre formulaire de contact.

Fiches disponibles : Nitruration - Nitrocarburation - Cémentation - Carbonitruration - Trempe par induction - Traitement thermique des alliages légers - Argenture - Nickel Chimique - Anodisation - Etain-Zinc.

Des technologies

de pointe

Vos préoccupations animent notre quotidien.

Vous recherchez des solutions pour optimiser vos coûts, augmenter la fiabilité et la qualité de vos produits, développer votre capacitaire, HACER est à votre écoute pour travailler avec vous les projets que vous souhaitez nous confier. Un rythme d'investissements soutenu dans nos équipements et une veille technologique constante nous permettent de suivre les évolutions techniques afin de répondre aux exigences du marché et à ce que vous recherchez en termes de :

- protection contre la corrosion

- amélioration du coefficient de frottement

- aspect

- conductivité

- intégration de technologies nouvelles (Argent dur / Argent partiel)

- ligne spécifique pour pièces fragiles

Trouvez ici toutes les combinaisons possibles chez HACER Traitements de Surface

Nos

procédés

En fonction du cahier des charges et de la nuance matière du produit, HACER vous propose des procédés adaptés aux pièces confiées. Pour vos pièces les plus fragiles et de petite dimension, une ligne entièrement automatisée, avec séchage intégré et adapté, fait du site de Marnaz un centre de compétences pour les pièces de connectique et à destination du secteur électrique-hybride-hydrogène.

Attache

Vrac

Bol vibrant

Les

substrats

Afin de répondre au maximum d'applications, nos traitements techniques s'effectuent sur divers substrats, en fonction des dépôts :

Acier standard

et alliages spéciaux

Inox

Maillechort

Aluminium

Laiton

Cuivre

Bronze

Quelques

applications

Véhicules électriques

Pour vous accompagner encore plus loin, HACER se positionne sur le marché des véhicules électriques et hybrides (EV / EHV) et étoffe sa gamme. A ce titre de nouveaux procédés ont été intégrés pour proposer des dépôts apportant à vos pièces une meilleure résistance à l'usure tout en assurant une bonne conductivité dans le temps (procédé Argent dur 160-200HV).

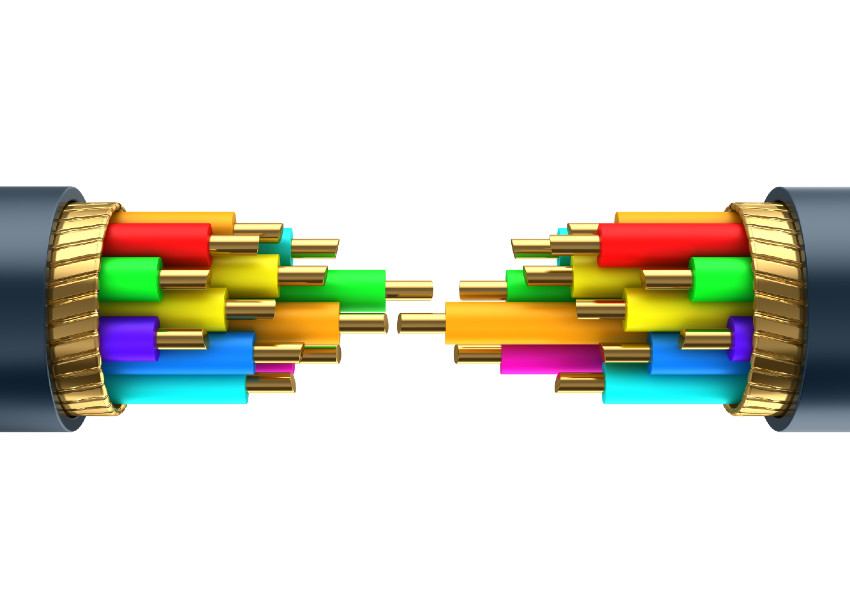

Connectique

Vous réalisez des pièces pour l'interconnexion des systèmes soumis aux environnements les plus sévères. HACER dépose des ors alliés sur vos contacts métalliques, pour assurer leurs propriétés de conductivité dans le temps.

Disjoncteur

Pour vos disjoncteurs “forte puissance”, une couche d'Argent (métal assurant une très bonne conductibilité électrique) de 8µm est déposée sur des pièces de contact pour assurer une très bonne conductibilité électrique.