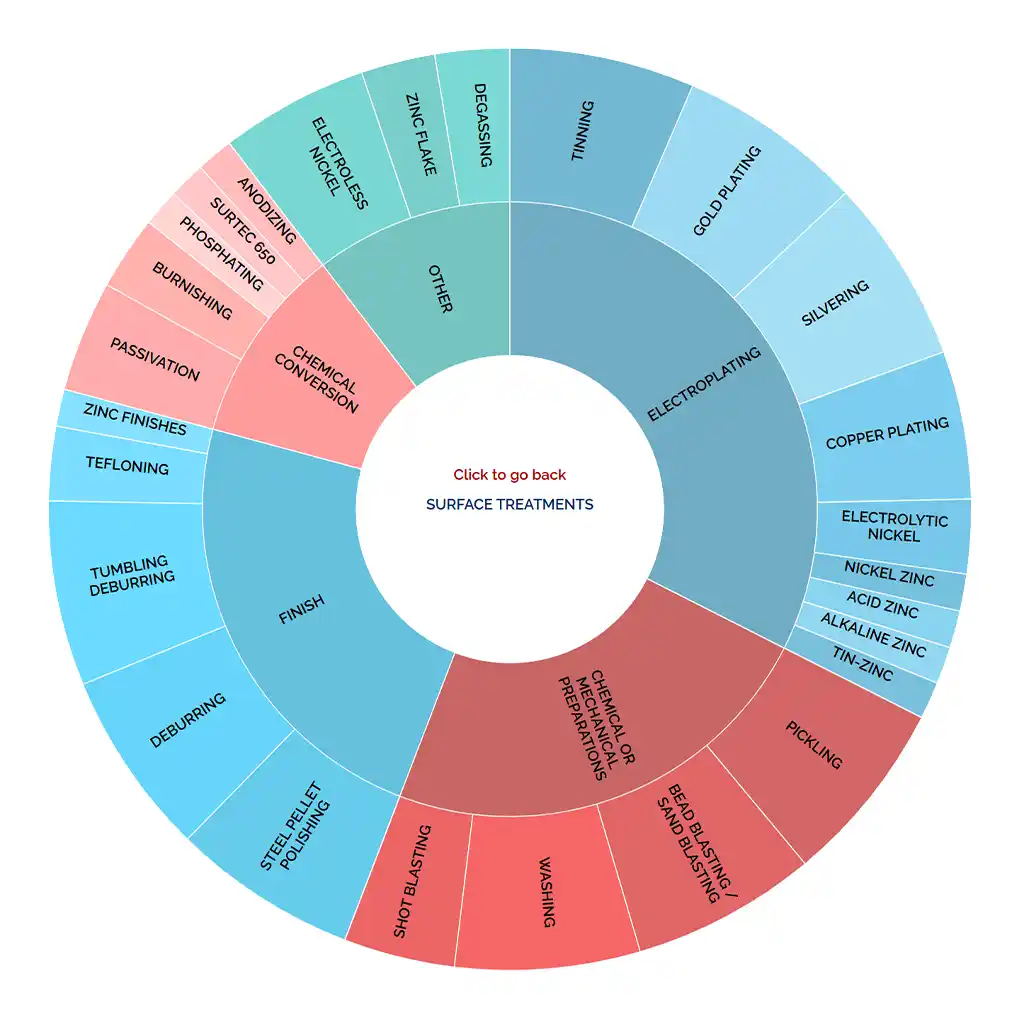

Our surface

treatments

Chemical conversion

- Passivation

- Phosphating

- Surtec 650

- Burnishing

- Anodising

Finish

- Steel pellet polishing

- Electrolytic polishing

- Deburring

- Barrel polishing

- Tefloning

- Bonded coating

- Zinc finishes

Chemical preparation

- Pickling

- Shot blasting / Sand blasting

- Washing

Electroplating

- Tinning

- Zinc nickel

- Electrolytic nickel

- Copper plating

- Acid zinc

- Alkaline zinc

- Gold plating

- Silver plating

- Tin-Zinc plating

Other

- Zinc flake

- Degassing

- Electroless nickel

For more details on our surface treatments, request the list of available data sheets via our contact form

Available data sheets:

Nitriding – Nitrocarburizing – Case hardening – Carbonitriding – Induction hardening – Heat treatment of light alloys – Silvering – Chemical Nickel – Anodizing – Tin-Zinc alloy plating

State-of-the-art

surface treatments technologies

Your concerns drive our daily work.

If you are looking for solutions to optimise your costs, increase the reliability and quality of your products, or develop your capacity, HACER is at your service and available to work together and develop your projects. A sustained rate of investment in our equipment and a constant technological watch enable us to monitor technical developments in order to meet the requirements of the market and find what you are looking for in terms of:

- Corrosion protection

- Friction coefficient improvement

- Appearance

- Conductivity

- Integration of new technologies (hard silver / partial silver)

- Specific line for fragile parts

Find all

possible combinations at HACER

Traitements de Surface here

Our processes

for surface treatments

Based on the specifications and the material grade of the product, HACER offers the processes adapted to your parts. For your most fragile and smallest parts, the Marnaz site is a specialised centre offering a fully automated line, with integrated and adapted drying.

Fastener

Bulk

Vibrating bowl

Substrates subjected

to surface treatments

In order to comply with the maximum number of applications, our technical surface treatments are used on various substrates, depending on the metal used for plating:

Copper

Bronze

Stainless steel

Standard steel

and special alloys

Nickel silver

Aluminium

Brass

Copper

Bronze

Stainless steel

Substrates subjected

to surface treatments

In order to comply with the maximum number of applications, our technical surface treatments are used on various substrates, depending on the metal used for plating:

Some applications

for surface treatments

Surface treatments of electric vehicle parts

HACER is taking it a step further, and positioning itself on the market of electric and hybrid vehicles (EV / EHV) and is expanding its range. In this respect, new processes have been integrated to offer plating processes or higher wear resistance for your parts while ensuring improved conductivity over time (160-200HV hard silver process).

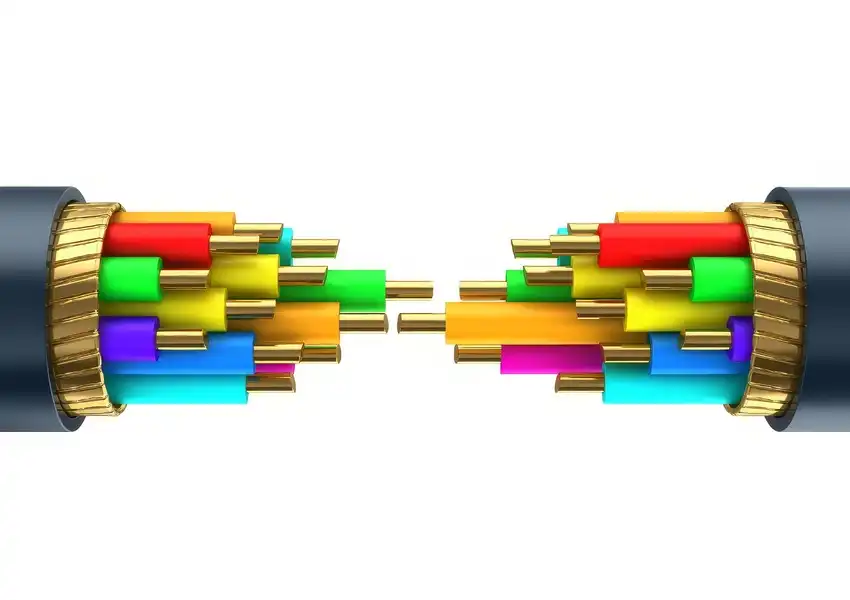

Surface treatments of connector parts

You produce parts for the interconnection of systems subject to the most severe environments. HACER uses gold alloy plating on your metal contacts to ensure their conductive properties over time.

Surface treatments of circuit breaker parts

For your high-power circuit breakers, an 8µm layer of silver (metal ensuring very good electrical conductivity) is deposited on the contact parts to ensure very high electrical conductivity.