Our heat

treatments

Vacuum heat treatments

- Structural hardening

- Hyperquenching

- Nitriding

- Oxy-nitrocarburizing

- Annealing

- Magnetic annealing

- Stabilization

- Quenching and tempering

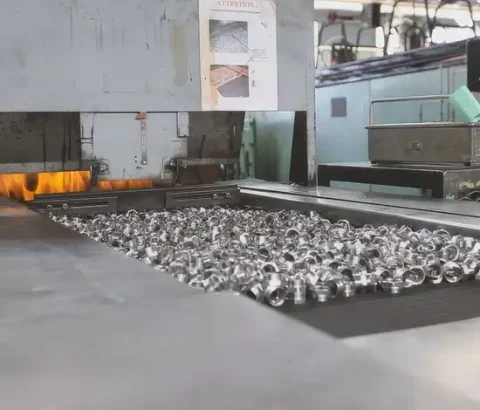

Atmosphere heat treatments

- Carbonitriding

- Case hardening

- Selective case hardening

- Annealing

- Tempering

- Stabilization

- Quenching and tempering

Heat treatments of light alloys

- Annealing

- Stabilization

- Quenching and tempering

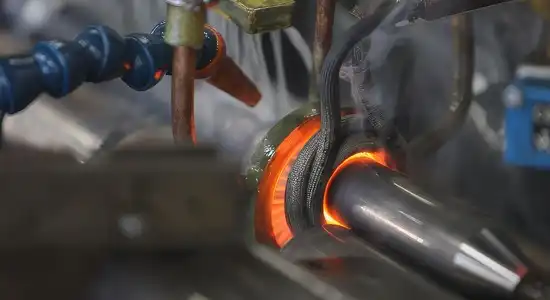

Induction heat treatments

- Tempering or partial annealing

- Quenching

For more details on our treatments, request the list of available data sheets via our contact form.

Available data sheets:

Nitriding – Nitrocarburizing – Case hardening – Carbonitriding – Induction hardening – Heat treatment of light alloys – Silvering – Chemical Nickel – Anodizing – Burnishing.

State-of-the-art

heat treatments technologies

Your concerns drive our daily work.

HACER is at your service and available to work together on your heat treatment projects. A sustained rate of investment in our equipment and a constant technological watch enable us to monitor technical developments in order to meet the requirements of the market and your heat treatment needs for your parts.

- Increase fatigue resistance

- Wear resistance

- Coefficient of friction

- Impact resistance

- Optimise your costs

- Increase the reliability and quality of your products

- Develop your capacity

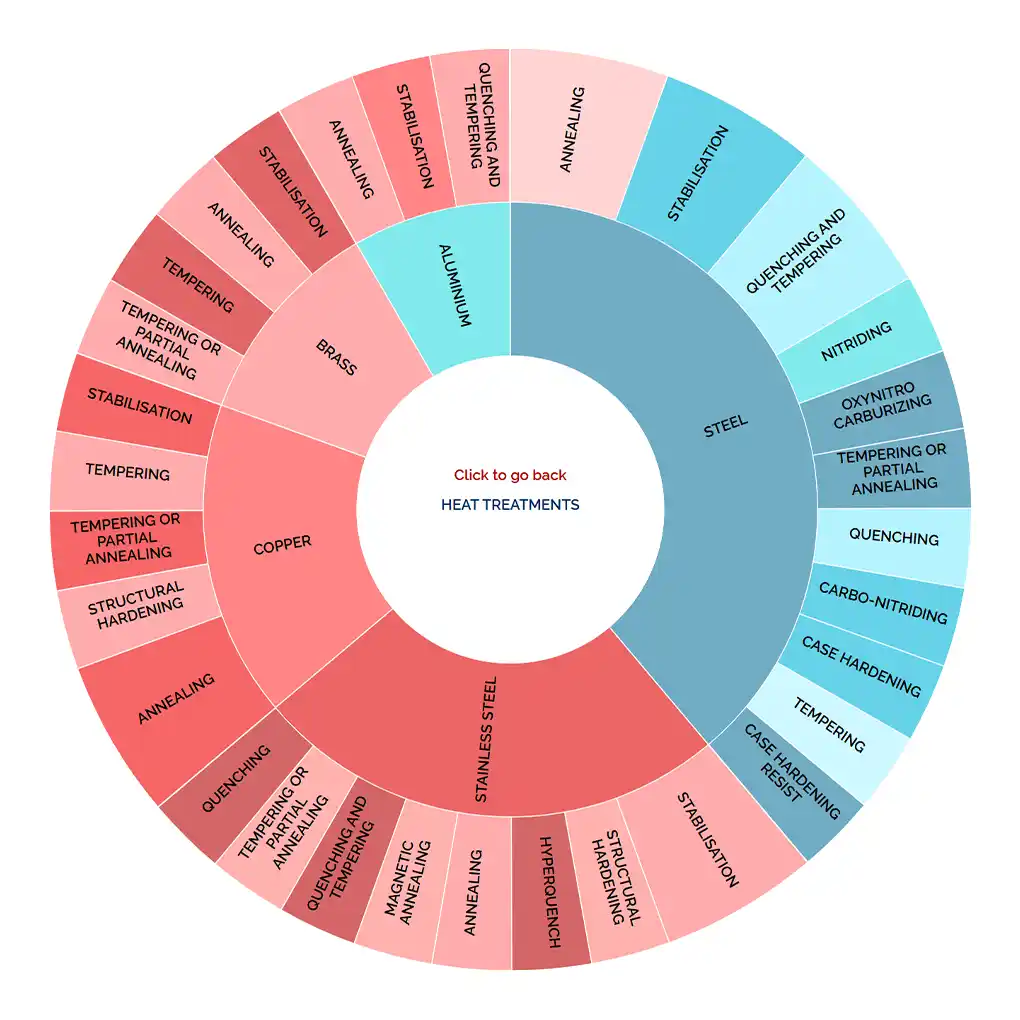

Find all

possible combinations at HACER

heat treatments here

Our equipment for

heat treatments

Based on the specifications and material grade of the product, HACER offers heat treatment processes adapted to your parts.

Batch furnace

Belt furnace

Induction hardening (HF – MF)

Steel

Stainless steel

Copper

Aluminium

Substrates subjected to

heat treatments

In order to comply with the maximum number of applications, our technical treatments are used on a wide range of metals:

- Alloyed and non-alloyed steels

- Structural, nitriding, case-hardening and carbonitriding steels

- Bearing steels

- Tool steels

- Stainless steels

- Aluminium alloys

- Copper, copper-beryllium

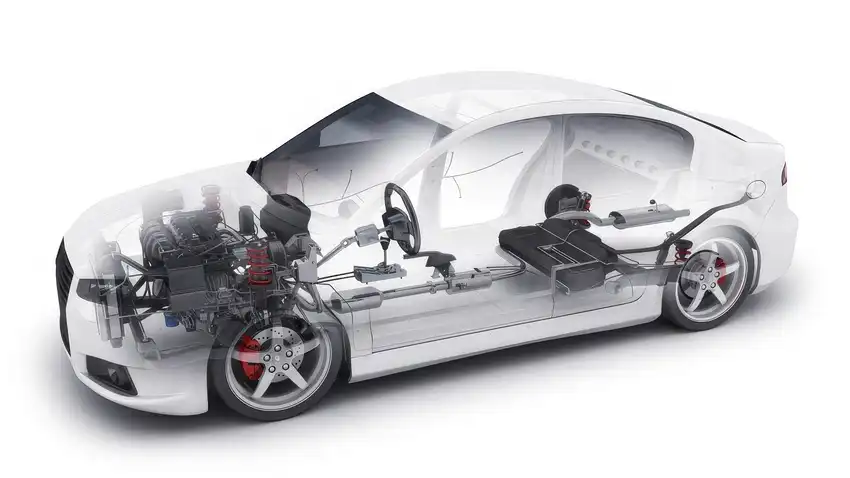

Some applications for

heat treatments

Heat treatments of

railway parts

HACER’s thermal process has been validated by an equipment manufacturer, and we are proud to ensure the treatment of tapered rollers and components of the bearings for the TGV of the future.

Heat treatments of

automotive parts

For one of our bearing manufacturer customers, we developed a heat treatment allowing to significantly increase the service life of gearbox bearings through a co-development project.

Heat treatments of mountain sports parts

HACER specialises in the heat treatment of aluminium, and provides mechanical properties to increase durability on your ski binding parts (ski touring or other), heel levers, etc.

For mountaineering carabiners, the parts that HACER treats as part of a global service package undergo a heat treatment for bulk hardening (7075 T73), as well as a sulphuric anodic oxidation (OAS).

Heat treatments of electric bike parts

In a growing market for standard bicycles or EABs (Electrically Assisted Bikes), it was necessary to solve the problem of a broken cold heading pedal spindle.

HACER ensures the heat treatment on pedal spindles (sometimes instrumented), by specific hardening and tempering, thus ensuring improved reliability and robustness over time.